Is your company struggling to find the benefits of a good manufacturing sampling or seeding program? Sampling programs allow your company to catch any discrepancies or feedback before your production is in full swing. Without a closed-loop strategy, your company might not be seeing the results you want or expected. Our sampling program helped Kensington™, a leader of desktop and mobile accessories, see a 7,000% increase in ROI.

Program Pain Points

Sampling programs can make or break your product’s success. Companies tend to write off sampling programs without realizing the benefits a good program can bring in terms of end-user sales and customer feedback. Here are some pain points Corrao Group has found for manufacturing companies managing their sampling programs:

-

- Trouble communicating the value of the samples

- Missed feedback opportunities from potential customers about your product

- No ability to track distributed samples

- Samples are not personalized to the end-user

- Difficulty collecting customer feedback during their unboxing to usage phases

- Lack of auto-escalation to resolution as issues arise

Corrao Group’s Solution

Kensington™ partnered with the Corrao Group to develop an automated way of managing sample units. After optimizing their Salesforce instance, Corrao Group helped develop and implement a closed-loop strategy that involved sampling out new products to new or existing customers. The sampling program would require a streamlined distribution strategy, tracking capabilities, hands-off reporting, and clear ROI. The white-glove experience would become known as “ProConcierge” and would involve Corrao Group creating and assisting in:

-

- Creating buyer personas to identify and prioritize qualified candidates

- Building a content map for supporting marketing collateral

- Creating weekly survey emails for the sampling program

- Packages carrying docking stations were tracked through Salesforce, and Pardot was connected to ensure that the appropriate feedback requests were automatically delivered weekly

- Customizing Salesforce reports to provide visibility into the leads generated weekly

- Standardizing Kensington™’s Salesforce process and implementing data requirements throughout their sales process

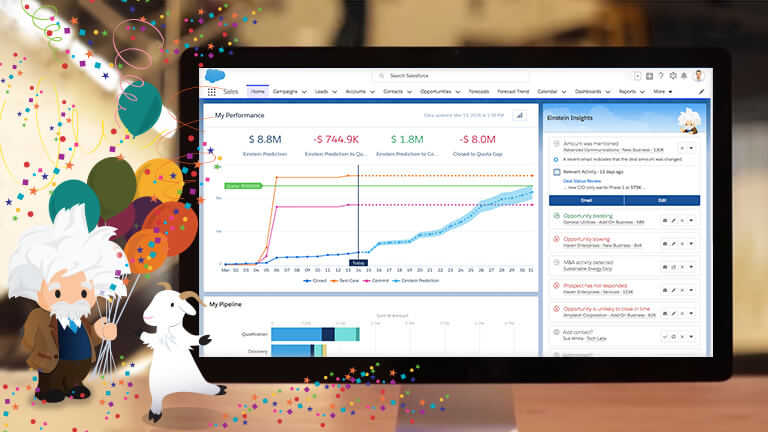

Salesforce Products Used

-

- Sales Cloud

- Pardot

- Einstein Analytics

Other Products Used

-

- Form Assembly

The hand-off process included the creation of step-by-step demonstration videos by the team at Corrao Group to assist with training as new users joined the ProConceirge team at Kensington™. In total, Kensington™ saw a 7,000% increase in ROI, $3M in influenced sales, and over 1,000 units shipped. To learn more about our assistance in ProConceirge, download our white paper.

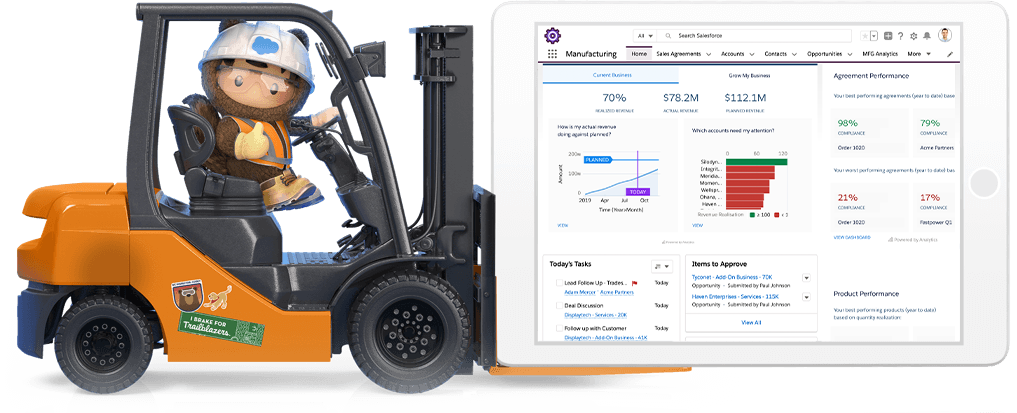

Salesforce’s Manufacturing Cloud

Our Sampling/Seeding program is exclusively built, configured, and optimized for Salesforce’s Manufacturing Cloud Platform. Manufacturing Cloud extends benefits to all your partners to collaborate across the same forecast order and demand data in one single source of truth. A new era is emerging for manufacturing, and it allows manufacturers to have complete control over the ability to operate their business in a much more profitable point of view.

Salesforce’s new Manufacturing Cloud will allow customers and their partners to have company-wide visibility into all their business processes. We understand that optimizing your Salesforce starts with optimizing your business processes. We’ve worked with nearly 1,000 customers; implementing, customizing, and optimizing Salesforce and have been everyday power users ourselves since 2008. Corrao Group can help you maximize your investments in Salesforce and Manufacturing Cloud. For more information, please visit our Salesforce page.